Inner Frame

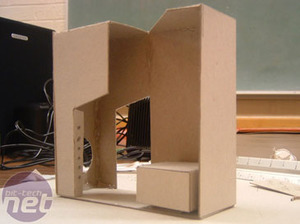

By now, we would hope that most readers are familiar with the edict "Measure Twice; Cut Once". To borrow another, the key to a complex mod is first to visualise, then attack. In this instance, Nick made clever use of some stiff cardboard to produce a mockup of his acrylic inner frame.

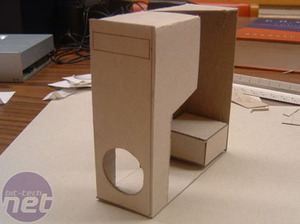

The entire design was shrunk to scale - the idea is to test the overall concept rather than worry about millimetre-perfect fit. Having satisfied himself that he was on the right path, Nick then switched from cardboard to black foamcore board and mocked things up in the full size outer frame.

Originally, the inner frame was going to be two pieces: one attached to the front panel; the other to the back panel. However, there turned out to be so little clearence between the two that the best move was to just make them one piece. This discovery was a direct result of putting in the extra time at the beginning with the models - not such a waste of time now, eh?

The added benefit of the foamcore mockup panels is that Nick was able to use them as templates for the sheet acrylic. Speaking of which...

You can think of this acrylic inner frame like a heavily modified ClearPC that sits inside the ornamental wooden outer frame. All the key PC components bolt to this inner frame. Nick designed and fabricated this from scratch. This included milling all the slots for the expansion cards - which he claims produced cleaner edges than even the factory cut panels - as well as stealthing the DVD drive with the front bezel by attaching a flush-fitting strip of acrylic to the front of the tray.

The work is so clean, you would be forgiven for thinking it had been laser-cut to order, a common method for slicing & dicing acrylic for custom cases, amongst other purposes.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.